- HomeAll information at a glance

- ABOUT USFind out more about the company

- ServicesOur core competencies, your benefits

- EquipmentMachining capacity in numbers

- CONTACT USSend us an email or give us a call

Expertise without compromise.

Expertise without compromise.Through a highly experienced and skilled workforce and management team, precision machined parts are produced and delivered on time, to a superior quality, all within a serious business partnership.

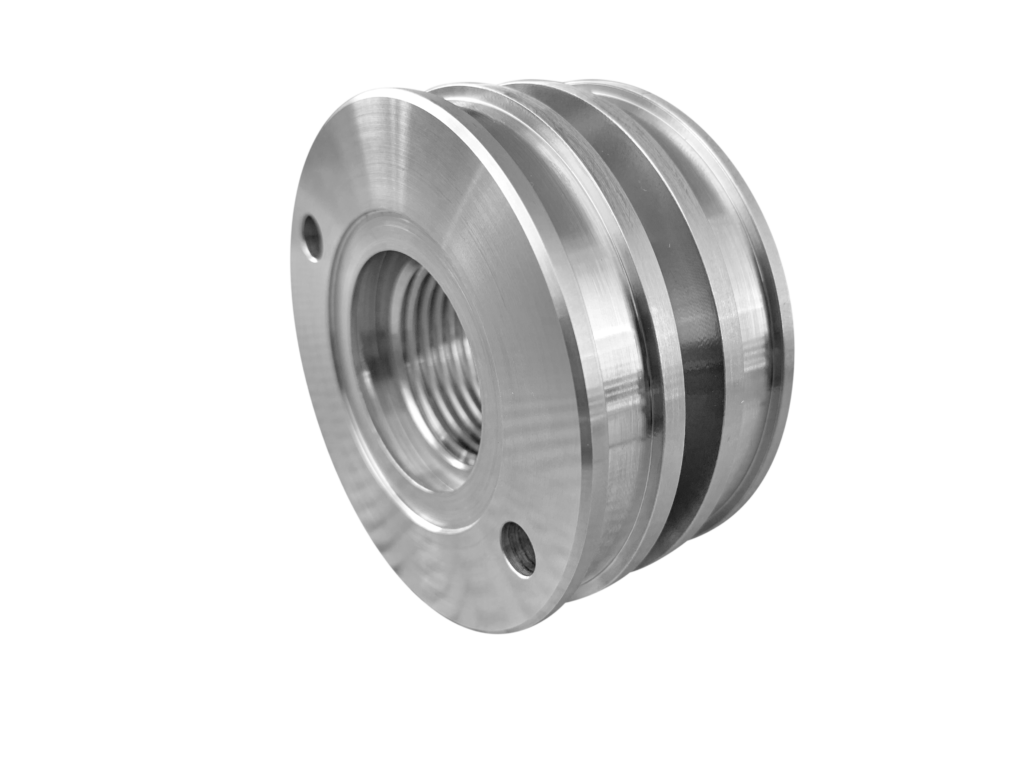

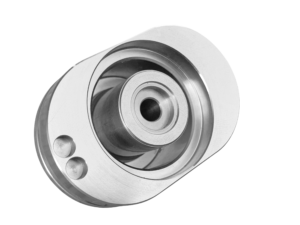

The precision CNC turning on high-end machining centers is our core competence. We are focused on middle-sized production batches with a min. turning diameter of 35mm of the turned parts.

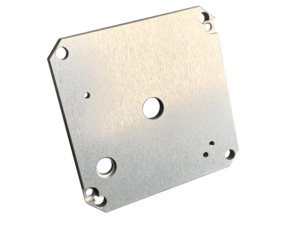

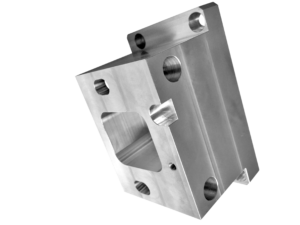

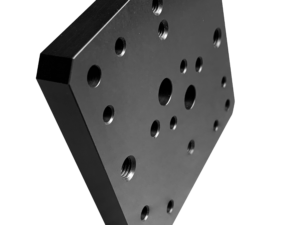

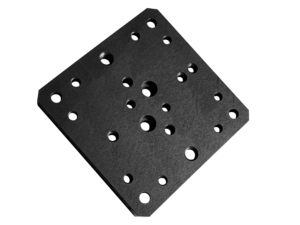

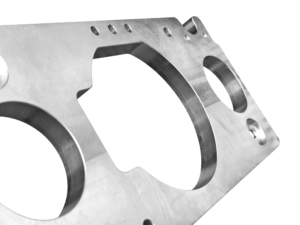

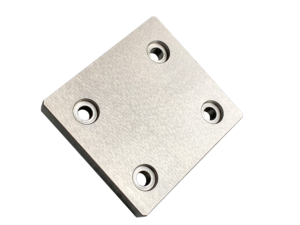

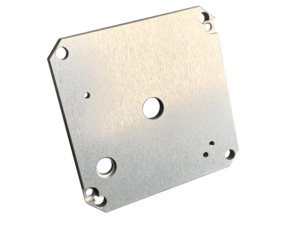

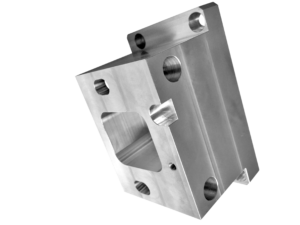

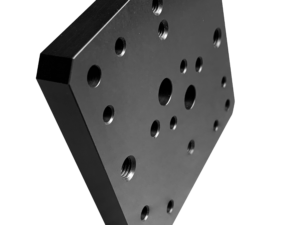

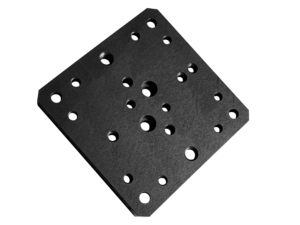

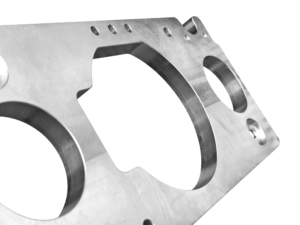

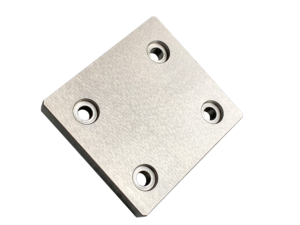

Get your complex milling parts produced at our factory on our 3-axis and 4-axis cnc machining centers. Profit from our extensive expertise in the precision cnc milling. Order your milled parts now.

We produce high accuracy grinded parts on our BLOHM CNC grinding center. We achieve tolerances in air conditioned environment up to 0.003mm accuracy.

Let us go one step further and we can deliver your cnc machined parts in our company even partially assembled for you. This is a logical step you would not want to miss.

scroll and check some examples of our work. We produce sophisticated cnc turning and milling parts using efficient technologies and delivering an outstanding quality to our valued clients. Promechanica utilizes all LEAN principles of a modern Industry 4.0 – oriented company.

scroll and check some examples of our work. We produce sophisticated cnc turning and milling parts using efficient technologies and delivering an outstanding quality to our valued clients.

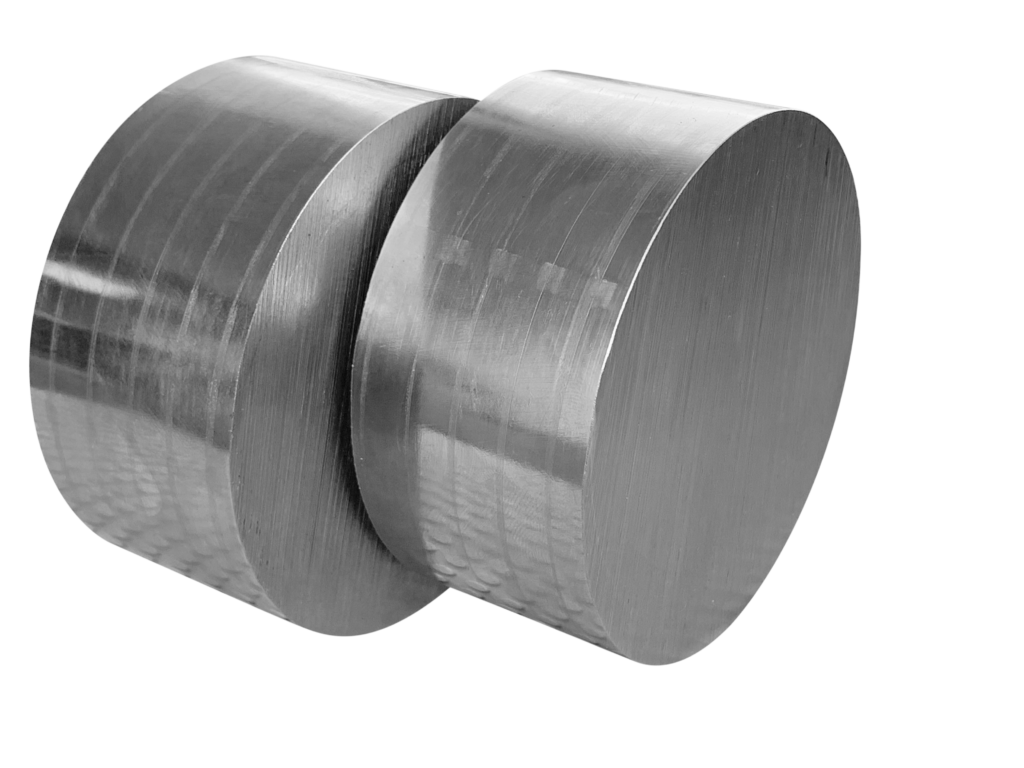

Our CNC turned parts are produced from high quality steel bars. The starting point of our production process are the billets – the delivered material is precisely cut into billets for our robotised turning centers. The requested materials are supplied by qualified suppliers. PROMECHANICA delivers the turned machined parts with material certificate according to EN 10204 3.1b.

Promechanica machines the following alloys:

STEEL GRADES

11SMnPb30 / S235JR / S355JR / 16MnCr5 / 42CrMo4 / 42CrMo4 +QT

STAINLESS STEEL GRADES

1.4301 / 1.4305 / 1.4404

Our strategic approach is set on machinig turning parts with a minimum diameter of 40mm and up to 180mm. The turning process at our factory starts from pre-cut round bars. Our robotisation process uses exclusively pre-cut billets. High degree of flexibility in the robotisation allows us short setup times of only five minutes from one to another turned part. Our partners receive fully finished parts including heat and surface treatment if requested.

The definite focus is set on optimisation of the machining cycles, high productivity and continuous controll of the requested quality of the turned parts.

We achieve tolerances in the precision turning in the range of 0.001mm. In most cases our turned components are with dimensions with tolerances in the range of 0.01 up to maximum 0.02mm.